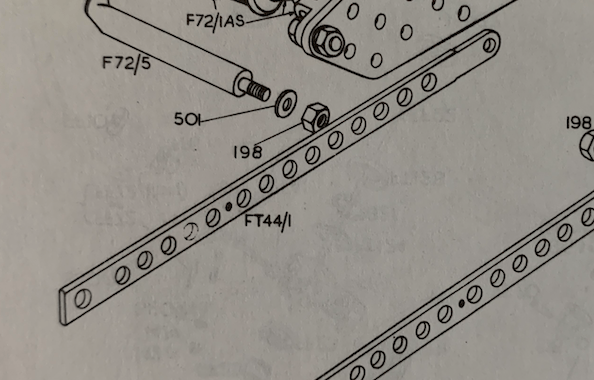

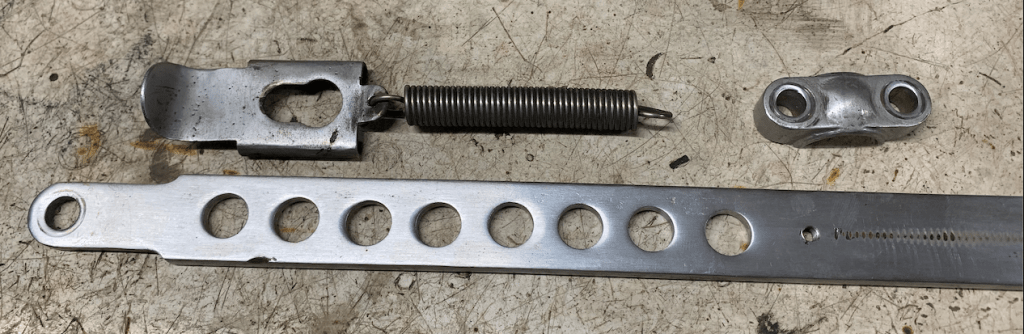

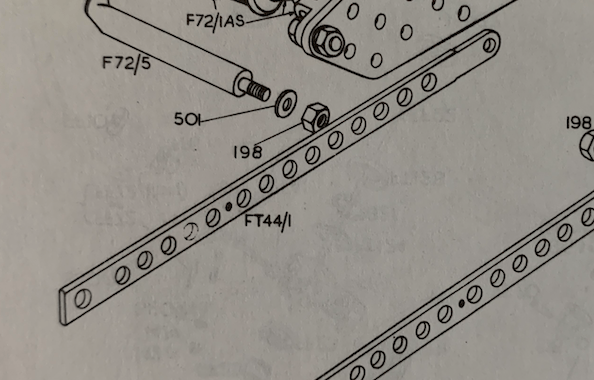

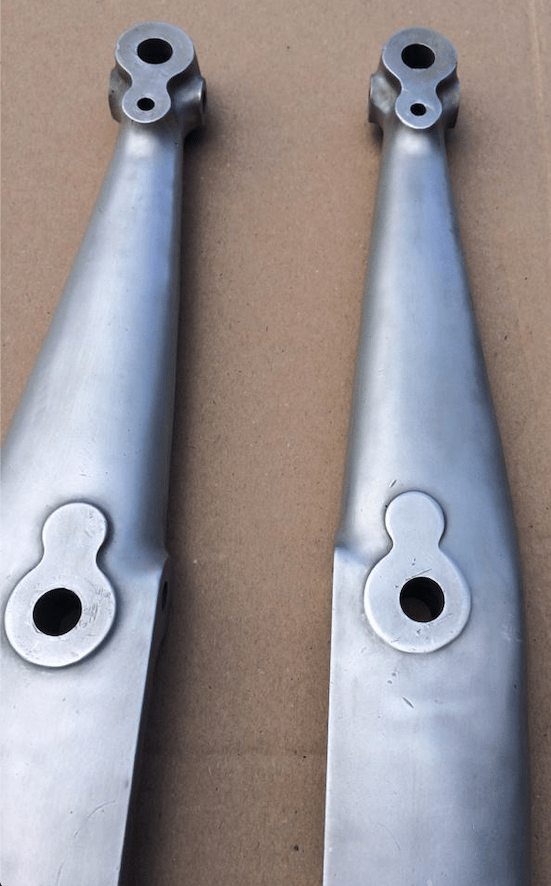

2751 is fitted with two drilled FT44 brake torque arms. These appear very similar to the items illustrated in the Spare Parts List.

These parts appear to be original to the bike and in fine condition – they will, of course, be left as-is.

2751 is fitted with two drilled FT44 brake torque arms. These appear very similar to the items illustrated in the Spare Parts List.

These parts appear to be original to the bike and in fine condition – they will, of course, be left as-is.

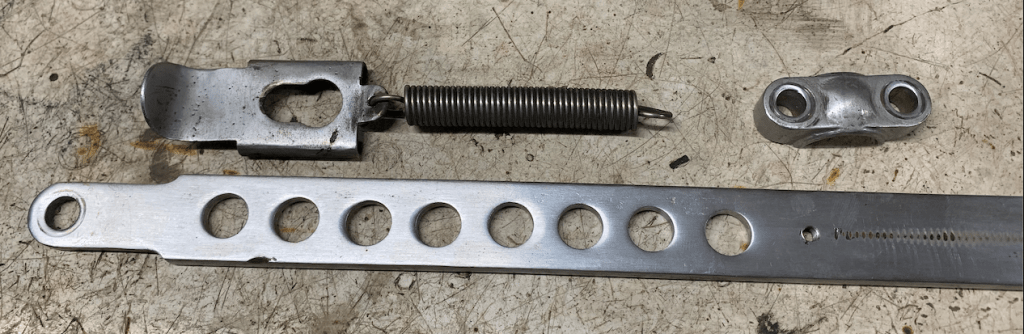

The F55 front brake balance beam is the one that came fitted to the 2751 when I acquired it.

We have no way of knowing whether this part is original to the bike or not, possibly not as it’s showing no signs of plated finish.

To my knowledge, these were not drilled at The Works and Grey Flashes were dispatched with regular undrilled items.

We cannot assume this part is original to the bike. But it has been on it a very long time, has period lightening modifications and, as such, is a valuable part of the bike’s history. It has been prepped prior to being dull chromium plated.

I had already bought a pair of hydraulic dampers from Maughan & Sons – these were ready-to-fit. The damper shrouds I had were another story though…

Not only were they terribly pitted and dented but some of the fixing screw holes had been wrecked. The one thing in their favour is that they were original items. Bert set to work…

This was a massive faff but the end result is well worth the effort expended. The shrouds and damper eyes will now be dull chromium plated.

The special Grey Flash pattern chainguard was not present on the bike so one need to be manufactured. A genuine, and somewhat battered, Comet item was procured from eBay, by myself, some years previously. Using period shots, Bert set to work cutting it and brazing on a bracket.

The finished chainguard is now ready to take to the platers. It would have been finished with a dull chromium plating.

Compared to the FF3 link, this assembly showed much more evidence of its original dull chromed finish.

Once the bearing races had been stripped from the assembly the chromed finish was found in an undisturbed state.

Cap screws had been added as “stops” to prevent the steering head from moving more than 15˚ either way – as stipulated by racing regulations.

This assembly will also be re-chromed. We now have all the evidence we need that it’s original to the bike and it will be given the correct protective coating enabling future owners to be in no doubt about how it would have appeared from new.

I would like to, once again, thank David Dunfey for his constructive and detailed comments on this assembly – a huge help.

Once the paint had been stripped off all the parts, we were not expecting to find that many of them were original to the bike. The fact that the bike had been raced hard, in several iterations, suggested that we were unlikely to find many original parts besides the main lumps, which we knew to be correct. As we know, being a very early example, 2751 had been subject to special finishes and attention-to-detail at The Works. So, any parts showing signs of dull chrome are, without any shadow of a doubt, certain to be genuine to the bike. The /1 suffix to the parts number differentiates this component from regular unplated links which were listed in the Parts List as ‘FF3’.

This is more than we could have hoped for and leads us to believe that the Girdraulic fork assembly stayed together as one lump.

Now we had to decide what to do; whether to have it re-finished or leave as-is. The latter is, of course, the preferred course of action. However, in this case, so little of the original plating is left that we feel that we are within our rights to have it re-finished in the correct dull chromium plate. Raw castings do not keep their plated finishes particularly well and the link has already started to rust in places. This will only get gradually worse unless the surface is protected.

The bushes have been removed and this part is ready to take to the platers at the end of this week.

The Grey Flash features an extensively drilled and lightened headstock casting.

The Works must have deemed this appearance a little unsightly so an alloy cover plate was devised to cover up the holes and provide a place for the mercury crest transfer.

I’m convinced this is original to the bike; accurately constructing a similar part wouldn’t be hard but correctly replicating the dimensions would require more diligence and it’s very unlikely anyone would have bothered with such a trifling task in decades past.

The question here is what might the original finish of this component have been? Usually they were polished. I feel certain that it wouldn’t have been blasted – some of the visible dings have also been subjected to this treatment indicating that the blasting was undertaken later on in the bike’s life. As the finish/presentation was a very important aspect of this early Grey Flash I suspect this plate would have been anodised along with many other of the aluminium parts. Re-anodising might be one answer or perhaps carefully removing the blasted finish with a suitable grade of wire wool. We need to have a careful think about this before coming to a decision.

One thing we’ve noticed about the drilling on the headstock casting is that it differs from that of later examples. David Dunfey has kindly sent me some images that show a different pattern of 5/16″ holes.

I’m finally able to report that the fork blades are stripped of all of their paint. In fact, all parts have now been stripped but I’m going to start with the forks as they are an important reference point for this part of the restoration. We know, without a shadow of a doubt, that the forks are the original ones that 2751 left the factory with. We know this because of the many unique features found on the Grey Flash Girdraulic fork legs that differentiate them from Vincent Black Lightning items. The bike was exported new to New Zealand; the only Grey Flash exported new to that part of the world. For the bike to have acquired a genuine replacement Grey Flash fork leg would have been nigh on impossible. So the legs have to be original to the machine and, under the paint, we are likely to find the anodised finish listed on the Works Record Card. That is, unless it was destroyed by someone trying to obtain a “key” for said paint…

As we have seen, the dull chromium plated finish extends to several parts of the machine, including the UFM and RFM. For now though, I will be concentrating on the parts of the bike that were anodised. This method of finishing alloy parts has been around since the ’20s though didn’t start to become widespread, beyond military applications, until the late ’50s/early ’60s. We were sure that the anodised finish would have been of silver in colour and that this would have been done to give the aluminium parts a superior appearance and protect them from oxidization.

Several layers of paint were removed exposing the finish beneath – the first time it’d seen the light of day in many decades.

To see how these legs differ in appearance from an unanodised set, prior to being painted, they will need to compared to an original leg in that state. I have an original leg, that’s never been refinished, elsewhere and I have a plan to dig it out, strip some of the old finish off and compare it to these ones. Then, I believe, the difference in finish will be quite apparent. Looking at these items on their own, they don’t appear to be showing any signs of anodising but I feel confident that this finish is indeed consistent with silver anodising albeit somewhat aged.

Anyway, for the time being, let’s just marvel at them. For sure, few have ever set eyes on a set of genuine Grey Flash lightened Girdraulic fork legs…

So, it is imperative that we are able to feel completely confident that the fork legs are indeed anodised. Once this has been confirmed then we will be able to use their finish as a point of reference when comparing them with other alloy components that we believe may be finished similarly.

Last night Bert sent through some images that I’ve been eagerly awaiting…

We know that 2751 left The Works with special finishes because the Record Card states: “Girdraulic anodized” and “dull chrome” as the finish for the petrol tank. However, we were not sure which other parts would have been finished thus and it was with great anticipation that we reached the point in the restoration process where we would be able to strip off the paint and see what was underneath. The beautiful cellulose paint applied by Terry Prince and Peter Johnson was a uniform finish and we knew that some parts were original to the bike, due to their rarity, whilst others might be correct but not the parts that 2751 left the factory with. Stripping off the layers of paint would reveal all and we would be able to ascertain what was what.

Some years previously I had rubbed a little paint off the rear forks and had been presented with a finish that indeed appeared to be a chromium plating of some kind – this patch didn’t rust over the years that it was left exposed.

Bert set to work on the UFM and RFM with 2 gallons of thinners. He toiled away for two days, high as a kite on the fumes whilst feverishly rubbing various layers away, his nub of a damaged thumb carefully protected from the vicious chemicals.

It is with a great sense of satisfaction – and even pride – that I’m able to reveal to the world, in this blog, the results of his hard work:

So, a real pivotal point in the restoration has been reached and every moment savoured! I hope all subscribers to this blog will find these images as satisfying as we are at being able to share them with you.

There has been a delay due to: (i) waiting on parts, (ii) the c-virus, and resulting lockdown, and (iii) to a medical emergency that resulted in ace spannerman Bert nearly losing his hand after a malevolent pathogen came out of nowhere and took hold… His full recovery will take some time but he’s now getting back in the workshop aided by his wife, when needed.

It took some time to ascertain what parts were needed to replicate the mudguards accurately. We decided it would be prudent to fit these up prior to the bike being completely stripped down.

The front racing-pattern mudguard is a standard alloy blade, minus the front u-shaped stay, and cut down. The rear stay is the standard item with a spacer between the stay and the fork to allow for clearance of the air scoops.

The rear racing mudguard is a purpose made item and not an adapted standard item.

The rear guard is almost a full 180˚ in circumference. The radius of the guard is the same as that of the front blade and it employs the leading u-shaped stay from the front, at the rear.

We were delighted to learn that these raw blades were actually in stock at the VOCS – this averted a special one-off order from a manufacturer, which is what we were anticipating.

And we’d like to thank Bob Culver for constructing the stays to original specification. They will be sent for dull chromium plating which would have been the original finish.